- My Forums

- Tiger Rant

- LSU Recruiting

- SEC Rant

- Saints Talk

- Pelicans Talk

- More Sports Board

- Coaching Changes

- Fantasy Sports

- Golf Board

- Soccer Board

- O-T Lounge

- Tech Board

- Home/Garden Board

- Outdoor Board

- Health/Fitness Board

- Movie/TV Board

- Book Board

- Music Board

- Political Talk

- Money Talk

- Fark Board

- Gaming Board

- Travel Board

- Food/Drink Board

- Ticket Exchange

- TD Help Board

Customize My Forums- View All Forums

- Show Left Links

- Topic Sort Options

- Trending Topics

- Recent Topics

- Active Topics

Started By

Message

Why do capacitors go out?

Posted on 8/29/23 at 2:36 pm

Posted on 8/29/23 at 2:36 pm

Pretty good read.

LINK

quote:

Some of the parts that fail the most often, especially in the summer, are run capacitors. Run capacitors are these little devices made of plastic sheeting with a metal coating and oil. They look like cans, and they help motors get up to speed.

A capacitor works like a pressure tank membrane or a balloon; instead of storing and discharging water or air, it stores and discharges electrons. Electrons make up the current, which we measure in amps. That electrical current goes to the compressor and outdoor unit fan motor to help them start up.

LINK

Posted on 8/29/23 at 3:13 pm to TigerGman

Think of them like a battery.

Batteries only have so many cycles before they give up.

Batteries only have so many cycles before they give up.

Posted on 8/29/23 at 4:59 pm to TigerGman

There were a lot of motherboard brands that used inexpensive liquid filled capacitors, where the caps would leak all over the motherboard, and short the board out. Most of the tech manufacturers of repute switched to solid capacitors a while back. I'm guessing that's not an option in a high amperage application like HVAC.

Posted on 8/29/23 at 10:00 pm to TigerGman

Changed my 1st capacitor this weekend. Local AC guy wanted $400 to change it. Got him to show me how to change it myself. Went to a local colburns and bought 2 just incase. $50 a piece and was done in less than 5 min

Posted on 8/29/23 at 10:09 pm to sonoma8

Changed the capacitors on the rear motherboard of my fridge for about $11 many years ago, at least 10 years ago. Saved $500-700.

Posted on 8/30/23 at 5:27 am to TigerGman

quote:

Why do capacitors go out?

They are an electrical device made by man.

Posted on 8/30/23 at 8:24 am to TigerGman

as an electrical engineer here is what I know

yes, capacitors do store energy, but this is in DC circuits

Compressors run on AC and capacitors have a different use in AC circuits.

What capacitors DO in AC circuits is cause a phase shift forward 90deg of the current with reference to the voltage. This has the benefit of power factor correction or supplying VARS to inductive loads (like motors). (Perfect) Inductors cause the current to lag 90deg with reference to the voltage.

However, this is just one of the uses for the 90deg forward shift. A HVAC compressor motor is a single phase AC PSC (Permanent Split Capacitor) type motor. Single phase motors have the issue of having zero start torque due to a static magnetic field that changes with the sine wave voltage. To solve this issue a PSC motor has two windings, a run winding and a start winding. The Run winding is connected directly across the voltage supply line and provides the main torque while running. The Start winding is connected in series with the capacitor and is offset 90deg from the Run winding. Now the purpose of the capacitor is to provide the 90deg phase shift for the start winding to create a starting torque for the rotor so it can start spinning.

Now why do they go bad? Well they are subject to an outdoor environment. They could lose oil. They are subject to many thousands of high current spikes that could eventually break a conductor inside due to fatigue.

yes, capacitors do store energy, but this is in DC circuits

Compressors run on AC and capacitors have a different use in AC circuits.

What capacitors DO in AC circuits is cause a phase shift forward 90deg of the current with reference to the voltage. This has the benefit of power factor correction or supplying VARS to inductive loads (like motors). (Perfect) Inductors cause the current to lag 90deg with reference to the voltage.

However, this is just one of the uses for the 90deg forward shift. A HVAC compressor motor is a single phase AC PSC (Permanent Split Capacitor) type motor. Single phase motors have the issue of having zero start torque due to a static magnetic field that changes with the sine wave voltage. To solve this issue a PSC motor has two windings, a run winding and a start winding. The Run winding is connected directly across the voltage supply line and provides the main torque while running. The Start winding is connected in series with the capacitor and is offset 90deg from the Run winding. Now the purpose of the capacitor is to provide the 90deg phase shift for the start winding to create a starting torque for the rotor so it can start spinning.

Now why do they go bad? Well they are subject to an outdoor environment. They could lose oil. They are subject to many thousands of high current spikes that could eventually break a conductor inside due to fatigue.

This post was edited on 8/31/23 at 10:16 am

Posted on 8/30/23 at 10:24 am to DVinBR

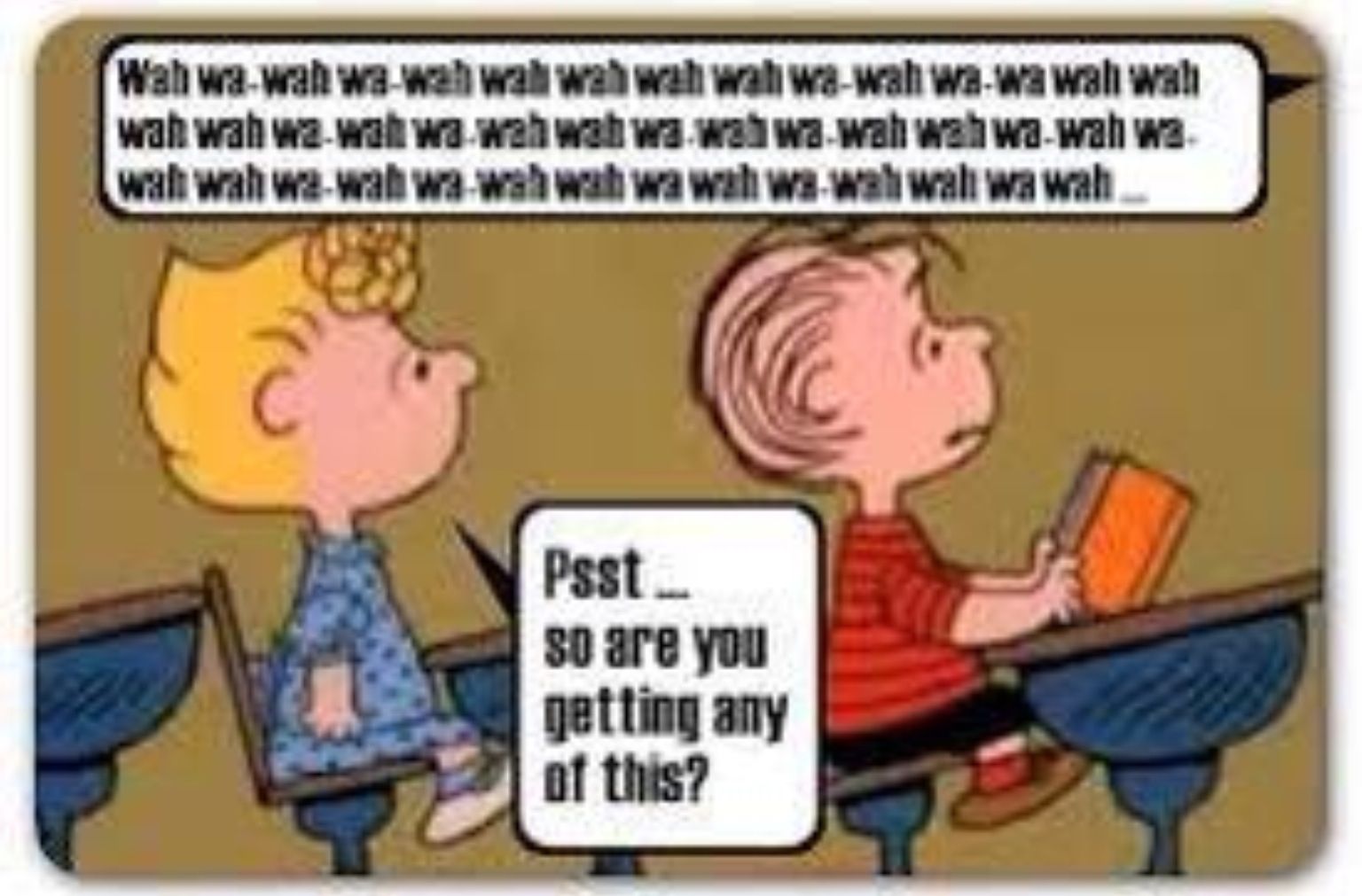

Are we going to be tested on this?

Posted on 8/30/23 at 10:49 am to TigerGman

Heat and voltage surges/spikes are the primary cause of capacitor failure - can’t do much about the heat, but you can help with voltage surges by installing a surge protector on the outside condensing unit - I had one installed with my HVAC changeout this past February.

Of course not all capacitors are made with the same quality - not likely to have many issues with a quality American made capacitor like AmRad as one will have with cheap Chinese made capacitors placed in many units.

Why Do Capacitors Fail (it’s not why you think)? (36 min Y/T video if you are HVAC nerd and interested).

Of course not all capacitors are made with the same quality - not likely to have many issues with a quality American made capacitor like AmRad as one will have with cheap Chinese made capacitors placed in many units.

Why Do Capacitors Fail (it’s not why you think)? (36 min Y/T video if you are HVAC nerd and interested).

Posted on 8/30/23 at 10:55 am to Jmcc64

quote:

Are we going to be tested on this?

Posted on 8/30/23 at 9:50 pm to DVinBR

quote:

as an electrical engineer here is what I know

You nailed it - a standard single phase PSC motor could not operate without that phase shift. You're essentially having to simulate a "second" phase like a 3 phase motor.

Now when we get into permanent magnet DC motors the game changes a bit. But so does the price - $$$$$$.

Posted on 8/31/23 at 9:42 am to DVinBR

What he is saying in layman's terms is that the motor needs a big bump to get it up to speed, this what that capacitor dose. Once its starts spinning at the rpms it needs to, the capacitor has done it's job and the voltage continues making it spin. I think of it like if you turn a ceiling fan on and immediately reach up and start the spin by hand. The capacitor is your hand doing the work until it gets up to speed. If I am understanding correctly. Am I close electrical engineers?

Posted on 8/31/23 at 12:04 pm to Shanegolang

quote:

Am I close

Yes. The capacitor is basically the Kickstart for the motor to get spinning.

Posted on 8/31/23 at 11:46 pm to DownshiftAndFloorIt

Does installing a soft start help re: this?

Posted on 9/1/23 at 6:53 am to DefensorFortis

They are two means to the same end. Think of the capacitor as a hard start.

Posted on 9/1/23 at 7:09 am to TigerGman

I imagine the weather has a lot to do with it.

Posted on 9/1/23 at 8:00 am to Shanegolang

quote:

Am I close electrical engineers?

Kind of. But there’s a difference between a start capacitor and a run capacitor. In general the difference between them is the current rating and capacity. A hard start kit is a starting capacitor with a relay and will be much larger than a run capacitor. This is the “kick start” of starting torque to get the motor up to speed and only stays in the circuit for about 0.25 seconds.

For the run capacitor, the phase shift is what creates torque on the motor for good efficiency and performance. This stays energized in the circuit 100% of the time.

This dude explains it fairly well: LINK

Posted on 9/1/23 at 9:46 pm to Shanegolang

quote:not on this

Am I close electrical engineers?

quote:

the voltage continues making it spin. I

Popular

Back to top

7

7