- My Forums

- Tiger Rant

- LSU Recruiting

- SEC Rant

- Saints Talk

- Pelicans Talk

- More Sports Board

- Coaching Changes

- Fantasy Sports

- Golf Board

- Soccer Board

- O-T Lounge

- Tech Board

- Home/Garden Board

- Outdoor Board

- Health/Fitness Board

- Movie/TV Board

- Book Board

- Music Board

- Political Talk

- Money Talk

- Fark Board

- Gaming Board

- Travel Board

- Food/Drink Board

- Ticket Exchange

- TD Help Board

Customize My Forums- View All Forums

- Show Left Links

- Topic Sort Options

- Trending Topics

- Recent Topics

- Active Topics

Started By

Message

re: New speed queen overflows 1.5" drain

Posted on 12/28/23 at 10:17 am to LEASTBAY

Posted on 12/28/23 at 10:17 am to LEASTBAY

I agree with the others, the most likely cause is partially clogged drain line that is reducing flow rate when the machine starts pumping water. I would start by making sure the drain is clogg free.

Posted on 12/28/23 at 11:42 am to MrBobDobalina

The pump is so powerful I think I will end up having to replace it in the end. Can I transition to PVC from metal with proflex clamps?

Posted on 12/28/23 at 2:11 pm to weadjust

quote:

Try bending the end of your drill snake at a 20 degree angle so it scrapes the inside of the pipe instead of punching a 1/4” hole in any clogs when the snake is straight at the end

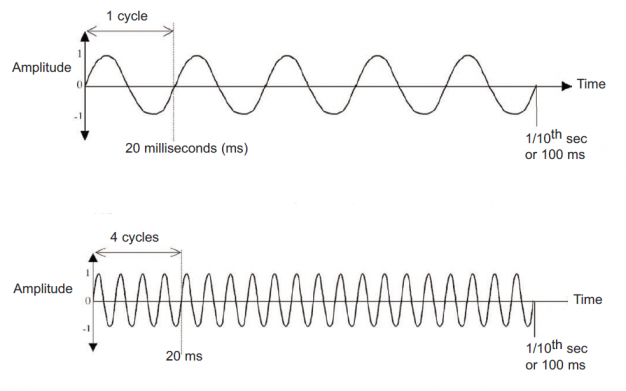

I am not saying that won't help in certain situations but when the snake spins it beats and scrapes the walls down the length of it. When you crank up the drill (or motor) the snake starts to look like a waveform.

Technically the tip is just for breaking through the clog or spinning into it and hooking into the mass to pull it out. The actual snake behind the tip is what really does the work of scraping the sides of the pipe. This is why when you have broken through and pulled out any nasty globs of hair and gungus you want to spin the drill fast and move the the snake in and out about a foot or so to scrape the walls clean down the length.

Posted on 12/28/23 at 2:28 pm to LEASTBAY

I had same issue with washer on a 1.5” line. First plumber tried to snake it from inside and couldn’t make it past p trap. Asked him to get on roof and go through vent stack. Said he couldnt for liability. What a crock of crap

Next plumber I called go on roof and worked his snake down and found severe roots in the drain line after the p trap. Ended up having to bust up concrete driveway and repair.

Next plumber I called go on roof and worked his snake down and found severe roots in the drain line after the p trap. Ended up having to bust up concrete driveway and repair.

This post was edited on 12/29/23 at 2:24 pm

Posted on 12/29/23 at 12:09 am to LEASTBAY

Yes that would be a suitable connection. Use a heavy duty one with 4 bands. Aka heavy duty no-hub band.

Posted on 12/29/23 at 12:28 am to MrBobDobalina

quote:

I'd be weary of putting any back-pressure on the pump.

As long as there is some water flow through the pump [to keep it cool] there is no danger of causing damage to the pump.

Posted on 12/29/23 at 9:25 am to TulaneUVA

Opened up wall a little. The pipe runs horizontal for a few feet until it connects to the sink drain. Can't get all the gunk out of the first elbow. Will try to remove the elbow as the whole pipe spins in the wall. Snaked it and did get the sink flowing better.

Posted on 12/29/23 at 9:43 am to LEASTBAY

Since the plumbing is connected to the sink drain. You could use some pvc and a fernco fitting to make a water tight connection from the washing machine to the wall. Then when the washing machine drains any backup will be contained in the sink & it can drain at a rate the plumbing can handle.

Posted on 12/29/23 at 10:30 am to weadjust

That's a good point. Next plan is to remove the elbow closest to the wall being it's very narrow with stuff cake inside of it. Then build out from there. Or maybe there's some sort of brush I can put on my drill.

Posted on 12/30/23 at 4:39 pm to LEASTBAY

Doesn't code call for 2" drain lines?

This post was edited on 12/30/23 at 5:48 pm

Posted on 12/30/23 at 7:04 pm to i am dan

On a new house. Didn't always be that way. House is 50 years old. When they come out with new codes you don't have to go update everything. I did get it fixed. Cut the horizontal 1.5 pipe with a reciprocal saw and it was pretty clean past that point from my snake etc. used a proflex clamp and transitioned to 2" PVC trap and drain. Seems to be fine now.

The drain where it connects to the tee behind the sink seems to be 2". That tee has a 1.5" off to the left for the washer. It runs through a stud also. Would be a much bigger job to remove that tee and replace the pipe through the wall. Just need to test heavy duty cycles which pump more water out during the rinse and spin phase.

The drain where it connects to the tee behind the sink seems to be 2". That tee has a 1.5" off to the left for the washer. It runs through a stud also. Would be a much bigger job to remove that tee and replace the pipe through the wall. Just need to test heavy duty cycles which pump more water out during the rinse and spin phase.

This post was edited on 12/30/23 at 7:09 pm

Posted on 1/3/24 at 12:16 am to LEASTBAY

I bought the Maytag commercial washer and when I put it in I damn near flooded my house. It pushed so much water through the drain pipe it just came gushing out. My old washer used far less water so I never had this problem. I just had to get my pipes cleaned out. Haven’t had an issue since.

Posted on 1/4/24 at 7:43 am to Tiger2375

Speed Queen makes an adapter for this situation. It's just a rubber piece that goes into the pipe and your discharge hose attaches to it. I had the a similar problem and it solved mine. Although I didn't have water pouring out, just some suds coming up back through the pipe and making the floor wet.

Hose Adapter 36878

Hose Adapter 36878

This post was edited on 1/4/24 at 7:46 am

Posted on 1/5/24 at 11:10 pm to LEASTBAY

I had the exact same issue whe we installed the Speed Queen. Those crappy new age machines that use fairy dust and hope to clean clothes also clog the pipes. Have it snaked out once and the water that the new machine uses will keep it clean.

Posted on 1/5/24 at 11:18 pm to TBoy

quote:

Hose Adapter 36878

Came with the machine.

Everything working well now after replacing with PVC. The elbows were really reduced in diameter with hard stuff caked on them. Snaked the whole thing and it is flowing well now.

Popular

Back to top

0

0