- My Forums

- Tiger Rant

- LSU Recruiting

- SEC Rant

- Saints Talk

- Pelicans Talk

- More Sports Board

- Winter Olympics

- Fantasy Sports

- Golf Board

- Soccer Board

- O-T Lounge

- Tech Board

- Home/Garden Board

- Outdoor Board

- Health/Fitness Board

- Movie/TV Board

- Book Board

- Music Board

- Political Talk

- Money Talk

- Fark Board

- Gaming Board

- Travel Board

- Food/Drink Board

- Ticket Exchange

- TD Help Board

Customize My Forums- View All Forums

- Show Left Links

- Topic Sort Options

- Trending Topics

- Recent Topics

- Active Topics

Started By

Message

Electrical / Pool Filter Question

Posted on 5/19/25 at 12:06 pm

Posted on 5/19/25 at 12:06 pm

I recently moved into a house with an above-ground pool. The pool is connected to a sand filter set on a timer. That outlet is ran back to my panel with a 14 gauge wire and a 30 amp. My inspection report stated that was a major concern as 14 gauge wire is not rated for a 30 amp.

Got an electrician to come out and he thought a 15 amp was tripping the pool filter and the previous homeowners put a 30 in to solve that. He suggested to swap back to a 15 and see what happens. The filter has not tripped but it has not turned off since he swapped the 30 for the 15 amp.

I read online that sometimes running a 30amp on a 14g wire can work if you only have 1 item running power on it (in this case, a pool filter).

Any suggestions? Fine with going back to a 30 amp? The filter timer was working while it was on that.

Got an electrician to come out and he thought a 15 amp was tripping the pool filter and the previous homeowners put a 30 in to solve that. He suggested to swap back to a 15 and see what happens. The filter has not tripped but it has not turned off since he swapped the 30 for the 15 amp.

I read online that sometimes running a 30amp on a 14g wire can work if you only have 1 item running power on it (in this case, a pool filter).

Any suggestions? Fine with going back to a 30 amp? The filter timer was working while it was on that.

This post was edited on 5/19/25 at 12:09 pm

Posted on 5/19/25 at 3:00 pm to Roy Curado

Breakers protect in-wall wiring and yours must be 15a. No way around that. If you need more power, you need a new circuit.

Sounds like 15a is plenty. If the pump takes 60a to start up for a second, it won’t trip the 15a breaker so you’re probably good and just need to keep an eye on it to see if it trips.

Also purposely, knowingly bypassing a safety device like that may be considered gross negligence (instead of regular negligence) meaning your insurance may have no liability at all if something bad were to happen.

Sounds like 15a is plenty. If the pump takes 60a to start up for a second, it won’t trip the 15a breaker so you’re probably good and just need to keep an eye on it to see if it trips.

Also purposely, knowingly bypassing a safety device like that may be considered gross negligence (instead of regular negligence) meaning your insurance may have no liability at all if something bad were to happen.

This post was edited on 5/19/25 at 3:09 pm

Posted on 5/19/25 at 3:40 pm to Roy Curado

Take a picture of the nameplate on the pump and post it. Can give more information then.

If the 15A breaker is holding, I would stick with it.

If the 15A breaker is holding, I would stick with it.

Posted on 5/19/25 at 4:04 pm to Roy Curado

I don’t see how the breaker has anything to do with the timer if it’s not tripping. Are you sure the electrician didn’t change anything on the timer settings?

This post was edited on 5/20/25 at 7:06 am

Posted on 5/19/25 at 6:11 pm to Roy Curado

Update your fire insurance.

14awg= 15A

12awg= 20A

10awg= 30A

Nameplate info on pump?

How far away is the pump from your service? Voltage drop could be an issue.

Circuit breaker in panel just supplies electricity to your timer/pump. Check to see if settings have changed in your timer.

Without seeing your setup, about all the info can provide right now.

Do NOT put that 30A breaker on 14awg wire.

14awg= 15A

12awg= 20A

10awg= 30A

Nameplate info on pump?

How far away is the pump from your service? Voltage drop could be an issue.

Circuit breaker in panel just supplies electricity to your timer/pump. Check to see if settings have changed in your timer.

Without seeing your setup, about all the info can provide right now.

Do NOT put that 30A breaker on 14awg wire.

Posted on 5/20/25 at 12:13 am to chrome1007

I accidentally broke off the end of the toothpick trying to reset it… oh joy

This post was edited on 5/20/25 at 12:23 am

Posted on 5/20/25 at 3:55 am to Roy Curado

What they are asking for is the motor nameplate which will either be a sticker or a riveted metal tag on the outside of the pump motor. It will look something like this

What people are looking for is the FLA (full load amps) number to see what current the motor needs. If it is a dual voltage motor (will have 2 numbers in the voltage line on the NEMA tag) we will need to know the voltage that it is wired on 120/240 because the current draw will be half at 240v compared to 120v. If it is on 240v it will have a dual pole breaker like the one below

Note a dual pole has the breaker switches tied together. While unlikely it is possible to have a 30a tandem breaker which has 2 separate circuits on it note how these switches are not tied together.

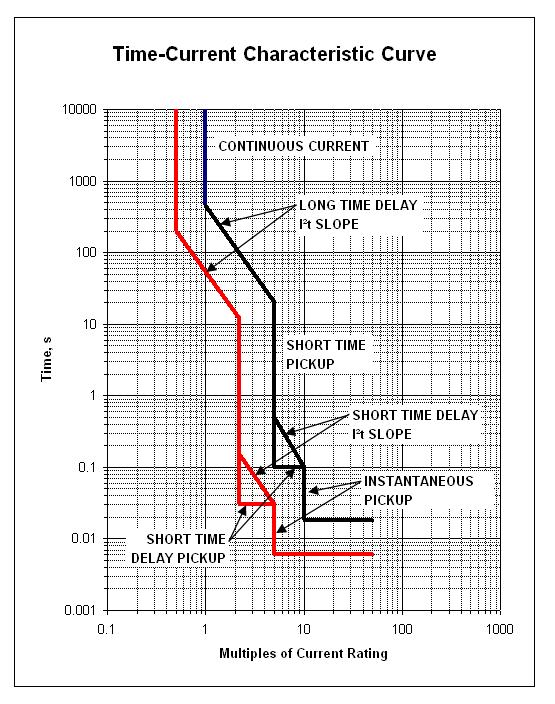

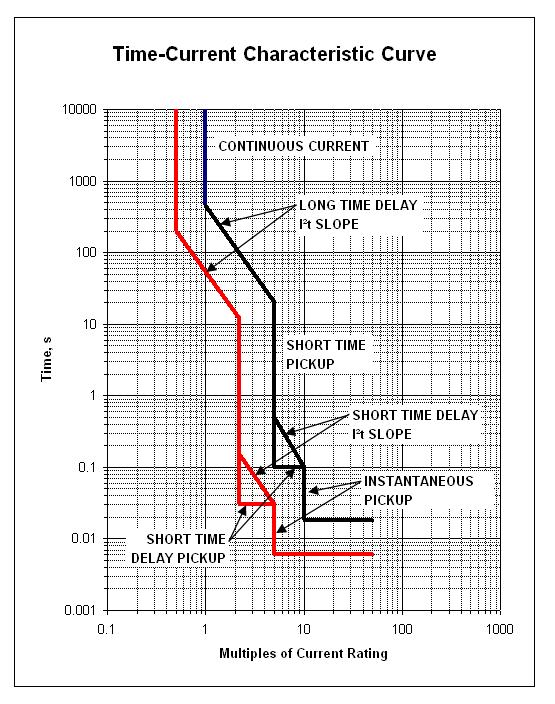

If the pump motor is 1.5 hp or less it is probably dual voltage and could be wired 120 or 240 but the FLA is going to be higher than 15a if it is 1.5hp and wired on 120v. Also while I didn't double check I would imagine the NEC 80% rule applies to pool pumps as a fixed continuous load. This means if you have a 15a circuit the FLA should not be more than 12 amps. Someone mentioned the current to start the motor will be significantly above the FLA, I have seen induction motors like pool pump motors at 10x FLA to start them. This is called inrush and only occurs for a short amount of time, so short a cheap multimeter won't register it, you need one with an inrush setting. This works because typical breakers do no trip the instant current goes over the breaker's rating. They have a time-current curve. TMI but a typical TC curve follows:

What people are looking for is the FLA (full load amps) number to see what current the motor needs. If it is a dual voltage motor (will have 2 numbers in the voltage line on the NEMA tag) we will need to know the voltage that it is wired on 120/240 because the current draw will be half at 240v compared to 120v. If it is on 240v it will have a dual pole breaker like the one below

Note a dual pole has the breaker switches tied together. While unlikely it is possible to have a 30a tandem breaker which has 2 separate circuits on it note how these switches are not tied together.

If the pump motor is 1.5 hp or less it is probably dual voltage and could be wired 120 or 240 but the FLA is going to be higher than 15a if it is 1.5hp and wired on 120v. Also while I didn't double check I would imagine the NEC 80% rule applies to pool pumps as a fixed continuous load. This means if you have a 15a circuit the FLA should not be more than 12 amps. Someone mentioned the current to start the motor will be significantly above the FLA, I have seen induction motors like pool pump motors at 10x FLA to start them. This is called inrush and only occurs for a short amount of time, so short a cheap multimeter won't register it, you need one with an inrush setting. This works because typical breakers do no trip the instant current goes over the breaker's rating. They have a time-current curve. TMI but a typical TC curve follows:

Posted on 5/20/25 at 8:20 am to Obtuse1

Thank you for this clarification. I am very ignorant to pools and anything electrical. Here is the motor. My panel is about 75’ from the pool filter. The 15 amp breaker on a 15awg wire (was previously 30) is ran to 4 outlets (1 is on GFCI and controls the rest) on the pool deck and then continues to the pool filter/timer.

This post was edited on 5/20/25 at 8:27 am

Posted on 5/20/25 at 3:53 pm to Roy Curado

CliffsNotes: you appear good on the electrical side, focus on the timer. The power interruption changing the breaker probably caused the issue. Maybe see if their is a factory reset.

I should point out I am not an electrician but I have more residential experience than most DIYers and quite a bit of experience running hard wired machines with induction motors in a residential setting ie woodworking shop with more than a dozen large machines running on both single and three-phase power.

On the surface everything looks fine on the electrical side. The motor should and apparently does run fine on a 15a 120v circuit. Voltage drop based on what you said should be under 5v when the pump is at full load. Well within the design parameters of most induction motors. I (maybe) should point out as voltage drops current draw increases but you are still fine though you may be pushing the 80% rule a little if it applies.

I would focus on the timer. I have an old school Intermatic mechanical timer so I can't help with the modern digital ones but there may be a factory reset.

TMI: the NEMA plate tried to make a liar out of me and to an extent I was a bit wrong. It is showing 1.5hp and only 12a @ 120v and I said it would be more than 15a if it was 1.5hp why typically is true but not with high efficiency motors. 1.5hp is 1112 watts so just under 10 amps at 120v but usually considering voltage drop and motor efficiency it is at or over 15a at full load. 12a like this motor lists is very low and would indicate an extremely efficient motor not likely to be found in a residential motor because the motors are expensive. However, this really isn't a 1.5hp motor. SPL after the hp rating indicates "special" rating ie bullshite. The motor only produces 1.5hp instantaneously. It is more like a 1hp motor. It is similar to Shopvacs that used to claim they were 5hp but had a 15 amp plug and ran at 12a or so full load. 5hp is over 3,700 watts so impossible to get from a 15a 120v circuit long term. They often rate those universal motors at locked rotor power. That is the amount of power the motor produces instantaneously when it is brought to a dead stop from full rpm. Technically, it isn't a lie and semi-useful when all the manufacturers use the same rating method but it is still marketing smoke and mirrors. Not dissing your motor just pointing out how the numbers don't always mean what they seem to say but NEMA motor plates are standardized so at least when you are using marketing puffery you have to indicate that on the motorplate even though 90% of people won't know what it means.

One last thing it probably doesn't meet code to have a permanent device (pool pump) on the same branch circuit as outlets. I think those have to be a home run. I say this mainly to caution against plugging too significant current draw devices into those outlets any time the pump can run. I would especially avoid sensitive (expensive) electronics since when the pump starts up (though for a very short time) there is a huge current inrush with the accompanying voltage drop that could take some electronics below their operating range think brown out. Phones charging are fine for numerous reasons.

I should point out I am not an electrician but I have more residential experience than most DIYers and quite a bit of experience running hard wired machines with induction motors in a residential setting ie woodworking shop with more than a dozen large machines running on both single and three-phase power.

On the surface everything looks fine on the electrical side. The motor should and apparently does run fine on a 15a 120v circuit. Voltage drop based on what you said should be under 5v when the pump is at full load. Well within the design parameters of most induction motors. I (maybe) should point out as voltage drops current draw increases but you are still fine though you may be pushing the 80% rule a little if it applies.

I would focus on the timer. I have an old school Intermatic mechanical timer so I can't help with the modern digital ones but there may be a factory reset.

TMI: the NEMA plate tried to make a liar out of me and to an extent I was a bit wrong. It is showing 1.5hp and only 12a @ 120v and I said it would be more than 15a if it was 1.5hp why typically is true but not with high efficiency motors. 1.5hp is 1112 watts so just under 10 amps at 120v but usually considering voltage drop and motor efficiency it is at or over 15a at full load. 12a like this motor lists is very low and would indicate an extremely efficient motor not likely to be found in a residential motor because the motors are expensive. However, this really isn't a 1.5hp motor. SPL after the hp rating indicates "special" rating ie bullshite. The motor only produces 1.5hp instantaneously. It is more like a 1hp motor. It is similar to Shopvacs that used to claim they were 5hp but had a 15 amp plug and ran at 12a or so full load. 5hp is over 3,700 watts so impossible to get from a 15a 120v circuit long term. They often rate those universal motors at locked rotor power. That is the amount of power the motor produces instantaneously when it is brought to a dead stop from full rpm. Technically, it isn't a lie and semi-useful when all the manufacturers use the same rating method but it is still marketing smoke and mirrors. Not dissing your motor just pointing out how the numbers don't always mean what they seem to say but NEMA motor plates are standardized so at least when you are using marketing puffery you have to indicate that on the motorplate even though 90% of people won't know what it means.

One last thing it probably doesn't meet code to have a permanent device (pool pump) on the same branch circuit as outlets. I think those have to be a home run. I say this mainly to caution against plugging too significant current draw devices into those outlets any time the pump can run. I would especially avoid sensitive (expensive) electronics since when the pump starts up (though for a very short time) there is a huge current inrush with the accompanying voltage drop that could take some electronics below their operating range think brown out. Phones charging are fine for numerous reasons.

Posted on 5/20/25 at 5:06 pm to Obtuse1

quote:

One last thing it probably doesn't meet code to have a permanent device (pool pump) on the same branch circuit as outlets. I think those have to be a home run. I say this mainly to caution against plugging too significant current draw devices into those outlets any time the pump can run.

My guess is this is why they changed it to a 30A.

Posted on 5/21/25 at 9:00 am to Obtuse1

I really appreciate your insight and comments. Thank you!

Posted on 5/21/25 at 12:59 pm to Roy Curado

My pool had to have a dedicated 20 amp breaker with 12 wire. Believe it stated that it has to be a GFCI as well, not sure on that part.

Popular

Back to top

4

4