- My Forums

- Tiger Rant

- LSU Recruiting

- SEC Rant

- Saints Talk

- Pelicans Talk

- More Sports Board

- Coaching Changes

- Fantasy Sports

- Golf Board

- Soccer Board

- O-T Lounge

- Tech Board

- Home/Garden Board

- Outdoor Board

- Health/Fitness Board

- Movie/TV Board

- Book Board

- Music Board

- Political Talk

- Money Talk

- Fark Board

- Gaming Board

- Travel Board

- Food/Drink Board

- Ticket Exchange

- TD Help Board

Customize My Forums- View All Forums

- Show Left Links

- Topic Sort Options

- Trending Topics

- Recent Topics

- Active Topics

Started By

Message

Posted on 6/12/24 at 6:02 pm to BIG Texan

Everyone feel free to laugh at my welds

Posted on 6/12/24 at 8:09 pm to VanRIch

eta: thanks for the honest update tho!

This post was edited on 6/12/24 at 8:15 pm

Posted on 6/12/24 at 10:18 pm to VanRIch

Grind it smooth, turn up the heat and try again.

Posted on 6/12/24 at 10:31 pm to VanRIch

I love it!

Yes it looks like shite. But you’re learning a new skill!! Grind it and hit it again!!!

Yes it looks like shite. But you’re learning a new skill!! Grind it and hit it again!!!

Posted on 6/13/24 at 6:26 am to Fat Batman

Yeah the wire keeps pushing me away. So I need to slow it down? I have a visor but I couldn’t really see what I was doing. It’s dark as shite. I’m afraid to take a shield out (I think there are 3) don’t want to burn my eyes.

Posted on 6/13/24 at 7:06 am to VanRIch

Way to get it done! It’s not art and doesn’t have to be pretty!

This post was edited on 6/13/24 at 7:10 am

Posted on 6/13/24 at 8:51 am to VanRIch

quote:

Yeah the wire keeps pushing me away. So I need to slow it down? I have a visor but I couldn’t really see what I was doing. It’s dark as shite. I’m afraid to take a shield out (I think there are 3) don’t want to burn my eyes.

I'm not a welder so take my advice with a grain of salt. But, I do have probably the same HF flux core welder that you have and Ive been able to put down some functional welds with it. I pretty much always run it on 5 and max, IIRC. I use both hands to maintain control. I keep my face/hood close enough so that I can see the puddle. there is a little push back but the wire should be melting into the puddle. I move the puddle slightly left and right while dragging backwards. speed at which i move the puddle is trial and error based on the thickness of the material. I think watching even just a single video on YouTube of people laying down some beads with that machine preferably where they show the puddle action would be a huge help for you. I would then take a piece of scrap and lay some 1-2" beads down until you feel like you have the hang of it. Then grind down your existing attempt on the deck and try welding it again. like the person above said it is true that it does not have to be pretty...but it does have to penetrate. stick with it, you'll figure it out and have a new skill

This post was edited on 6/13/24 at 8:53 am

Posted on 6/13/24 at 9:19 am to Fat Batman

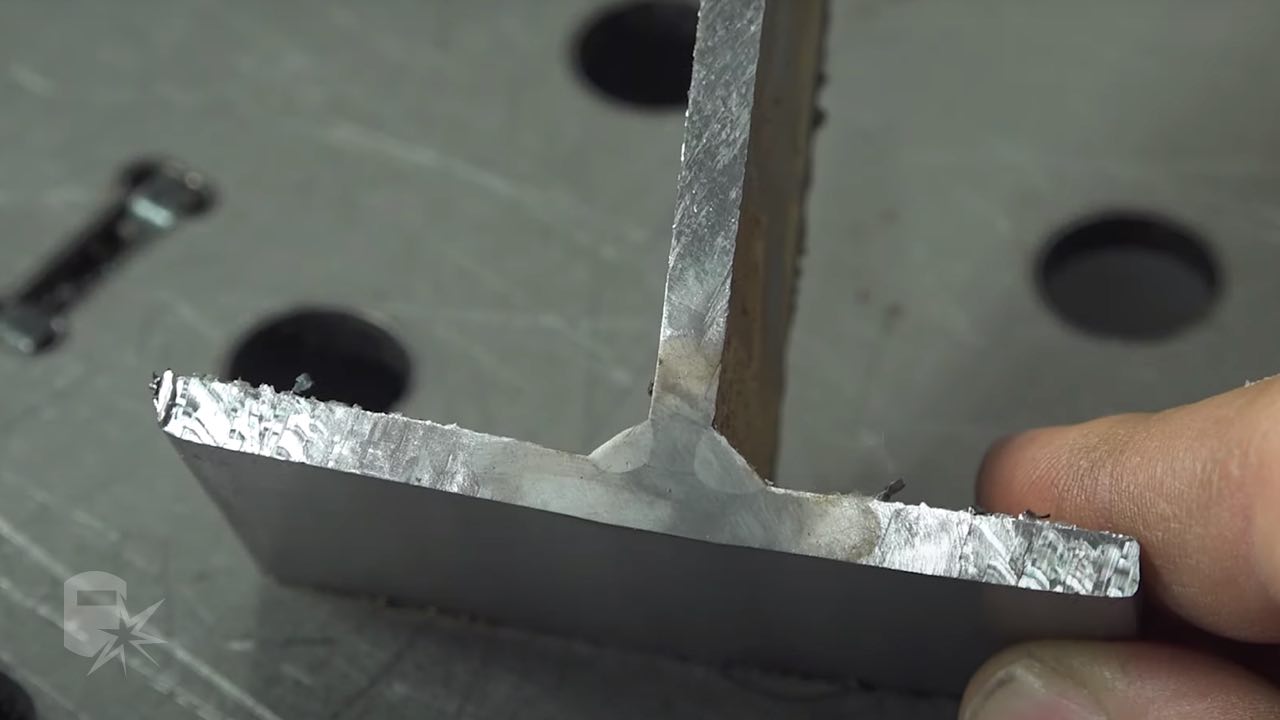

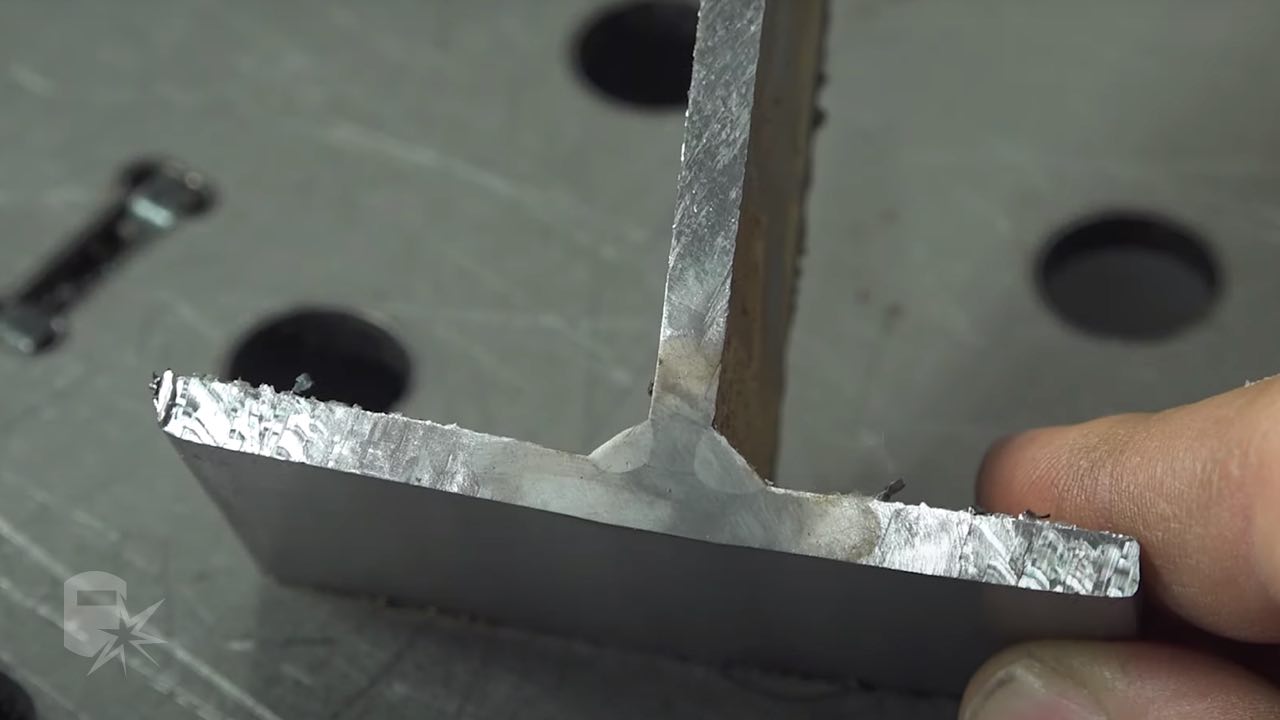

So when you say penetrate, does that mean the weld and metals both sort of “liquifying together” for a lack of a better term? I thought penetrate meant you have to have some rough surface for it to go into. I even drilled a couple smaller holes and welded into them to make some “bolts”. I don’t know crap about welding, obviously but I’m not opposed to grinding down and trying again. I guess there’s a fine line between cold welding and burning through your stock. This also doesn’t have to be extremely strong, I just need it to hold well enough to keep the wheel on and the deck level.

Posted on 6/13/24 at 9:35 am to VanRIch

yeah pretty much, penetration meaning your weld penetrates into the 2 pieces of metal you are trying to join liquifying all three parts together (bar, weld, bar). the below image cross section shows how the weld penetrates into both pieces of bar stock. if your weld is just sitting on top of the metal then it will not hold very well.

Posted on 6/13/24 at 10:18 am to Fat Batman

Just went outside and tried grinding a bit. Damn that flux wire gets HARD. Going to have to get a fresh disc.

Popular

Back to top

1

1